Smart Strategies to Improve Metal Fabrication Design Today

Every custom metal fabrication project starts with a good design. This design acts like a roadmap—it shows how your idea will be turned into a real product. When your design is clear and well thought out, it helps everything go smoother: production becomes more efficient, the final result is higher quality, and you can often save time and money. Below are six practical tips to help you improve metal fabrication design and bring your project to life successfully.

1. Work with Experienced Fabricators

One of the smartest moves is to team up with a metal fabrOne of the smartest moves is to team up with a metal fabrication shop that knows what they’re doing. A shop with a solid track record can guide you through material choices, suggest better design solutions, and help you avoid common mistakes. They’ve likely worked on projects like yours before, so their feedback can make a big difference.ication shop that knows what they’re doing. A shop with a solid track record can guide you through material choices, suggest better design solutions, and help you avoid common mistakes. They’ve likely worked on projects like yours before, so their feedback can make a big difference.

2. Be Clear About the Details

If you’re asking for a quote, make sure you provide all the important details. Include exact sizes, measurements, material type and thickness, how it should be built, and even things like how many fasteners are needed. The more specific you are, the easier it is for the fabricator to understand your needs and give you an accurate estimate.

3. Make Sure Your Design Is Complete

Think of your design as your project’s master plan. If it’s missing key information, it could cause delays or extra costs. Try to include technical drawings, specifications, timelines, and contact details for the person managing the project. A complete and organised design helps everything move forward more smoothly.

4. Test the Design First

Before moving into full production, it’s a good idea to test your design with a prototype. This helps confirm that the part or product works as expected and performs well under real conditions. You can start with 3D models, then move to a physical prototype if needed. This step gives you a chance to make improvements before large-scale manufacturing begins.

5. Pick the Right Material

The material you choose can make or break your project. It needs to handle the job it’s meant for—whether that’s strength, durability, corrosion resistance, or something else. Since materials are a big part of your budget, choosing the right one matters. Your fabricator can help you select a material that fits both your design needs and your budget.

6. Stick with One Fabrication Partner

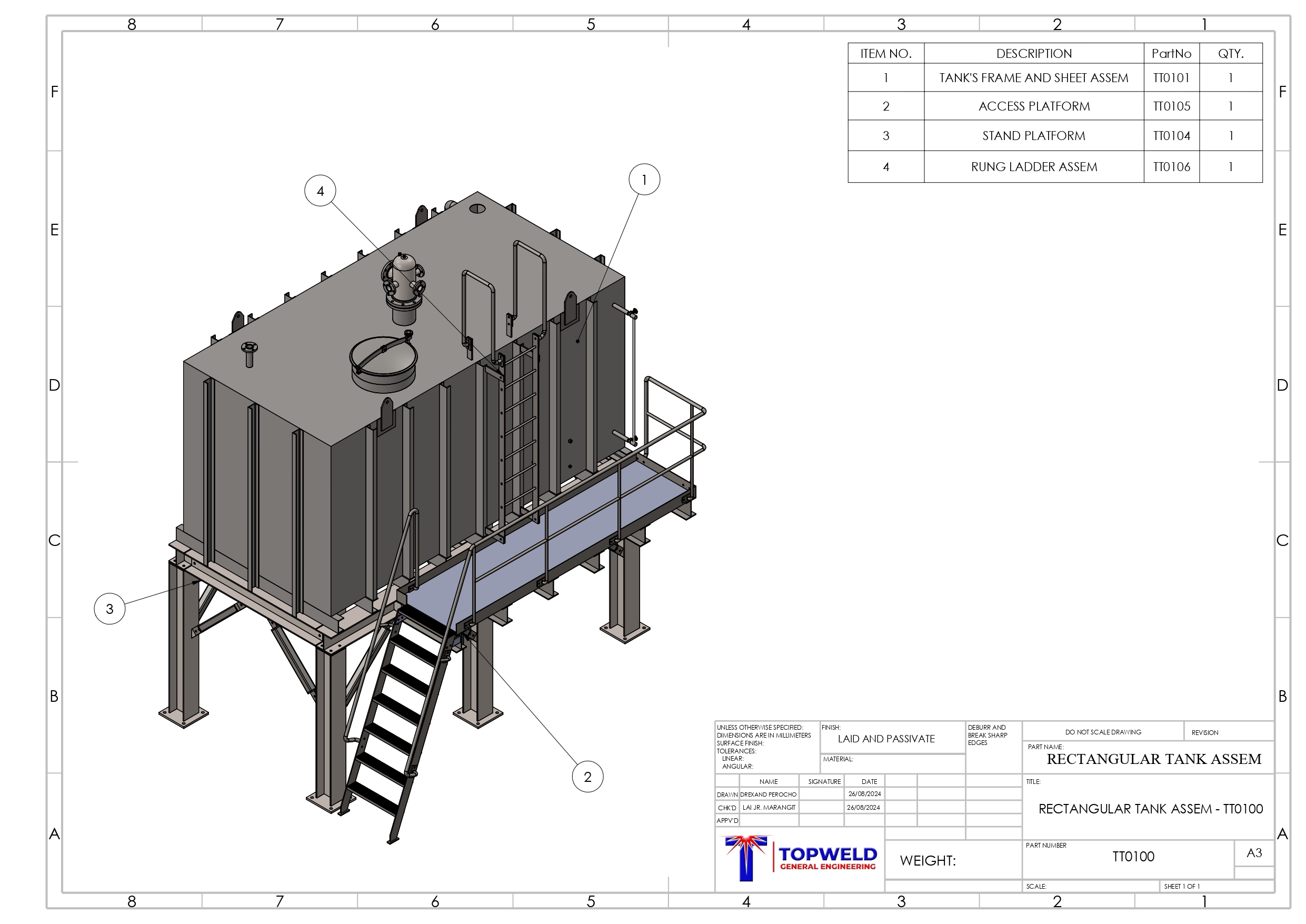

Choosing one reliable fabrication shop to handle everything—from prototyping to final production—can make the whole process simpler and more efficient. A full-service partner like Topweld can help you make design improvements early on and carry them through to a finished, high-quality product.

By putting these six simple tips into practice, you’re not just creating a design; you’re building a foundation for success. A great metal fabrication project isn’t just about what you build, but how you plan for it. From working with an experienced fabricator who understands your vision to making sure every detail is crystal clear, each step helps improve metal fabrication design, smooth out the process, prevent costly surprises, and ultimately deliver a product that exceeds your expectations.

Need help with your metal fabrication project?

Reach out to Topweld to find out how we can help you turn your design into reality—faster, better, and with fewer surprises along the way.