For any significant commercial or industrial construction endeavor, the expertise of structural steel fabricators is indispensable. This specialized field is the bedrock of robust infrastructure across every Australian industry. Unlike conventional construction materials such as concrete, timber, or aluminum, structural steel boasts an unparalleled strength-to-density ratio, making it the material of choice for demanding manufacturing, construction, and component applications. At Topweld General Engineering, we don’t just supply steel; we meticulously transform raw metal into the precise forms your vision requires.

Our team of seasoned steel fabrication specialists is often asked a range of questions about their craft. Here, they share their insights:

Definition of Structural Steel

At its core, structural steel is the specific grade of steel engineered for the skeletal frameworks of bridges, office complexes, warehouses, healthcare facilities, and a myriad of other critical structures. Its suitability hinges on possessing exact mechanical properties—including tensile strength, chemical composition, and precise shape—to align with project specifications. The fundamental elements of structural steel, like all steel variants, are iron and carbon. Additional components such as manganese, various alloys, and specific chemical agents are often incorporated to fine-tune its characteristics.

Its carbon content classifies it as a mild steel, yet this specific composition is what sets structural steel apart. Typically, the carbon concentration ranges between 0.15% and 0.30%. Exceeding this range can yield a material with exceptional strength but compromised ductility, while insufficient carbon reduces its structural integrity. The intended application of the steel dictates the optimal carbon level required.

The Art of Structural Steel Fabrication

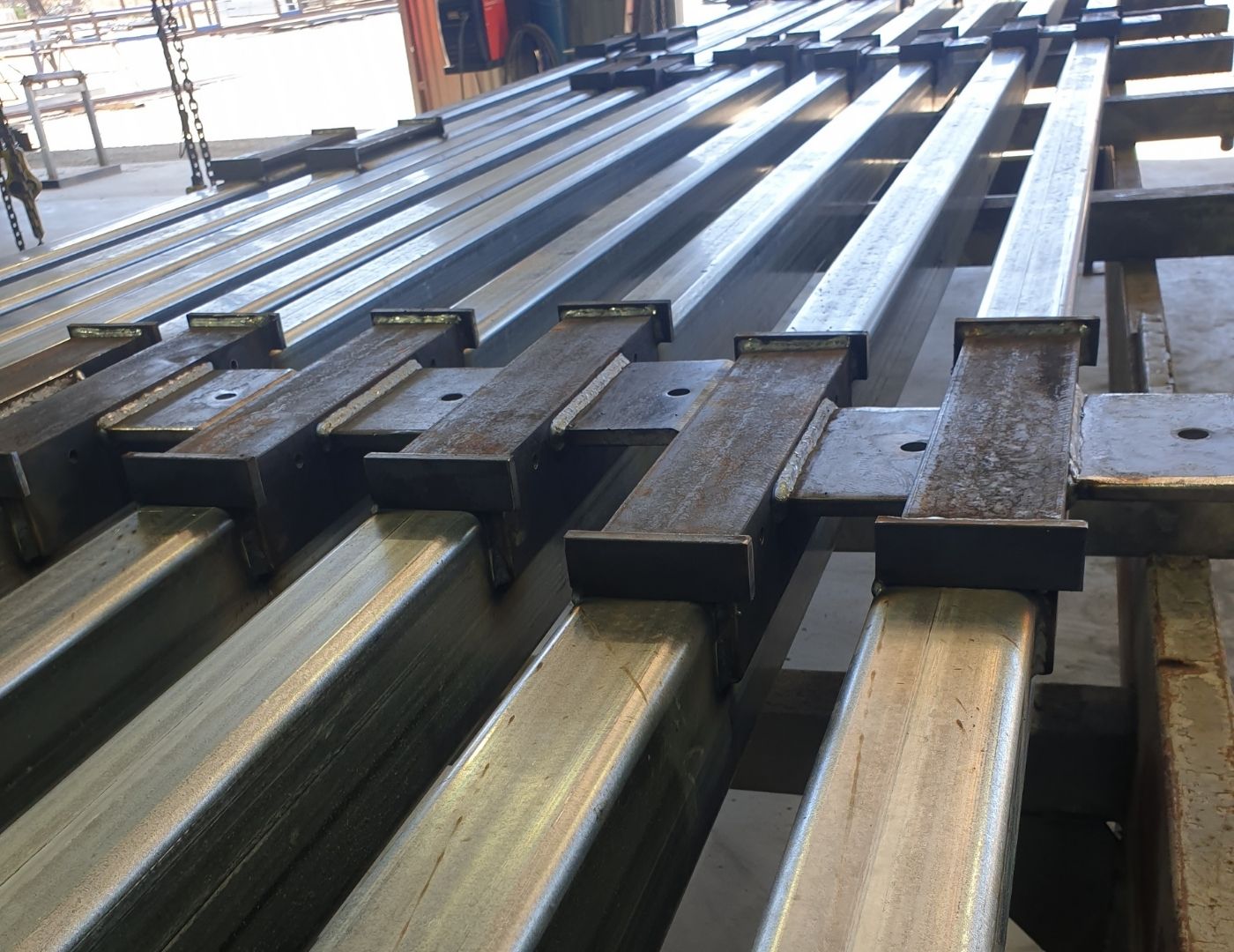

Structural steel fabrication is a sophisticated discipline, far surpassing the mere production of steel sections. It encompasses an intricate sequence of processes culminating in the assembly of a complete structure. Beyond the fundamental operations of cutting, bending, and joining components, our structural steel fabricators undertake the detailed preparation of the steel for its eventual role in a building or bridge. This involves translating architectural and engineering blueprints into highly detailed workshop drawings, selecting and managing the optimal materials, and executing precise procedures such as cutting, drilling, meticulous shop-fitting (including bolting and welding), and applying protective coatings like paint or galvanizing, all before coordinating for delivery and installation.

The Enduring Advantages of Structural Steel

Structural steel offers a compelling array of benefits for fabrication projects. Foremost among these are its superior mechanical properties: it is renowned for its exceptional durability, inherent corrosion resistance, high strength, tensile integrity, and relatively lightweight profile compared to its strength. Its remarkable adaptability and flexibility allow it to be precisely shaped, cut, and welded into virtually any form required by design.

Economically, mild and carbon steels often present a more cost-effective solution than alternative metals such as copper, aluminum, or magnesium used in construction. Beyond cost, structural steel is engineered for longevity. It withstands demanding conditions, performs robustly against severe weather, and can be engineered to resist seismic activity. Applied coatings can further enhance its fire and water resistance. Finally, its high recyclability underscores its position as an environmentally conscious building material, aligning perfectly with Australia’s commitment to sustainable construction practices.