From Concept to Creation: The Metal Fabrication Journey with Topweld General Engineering

Bringing a custom metal fabrication project to life requires a structured approach, meticulous planning, and precise execution. For businesses seeking tailored solutions, understanding the fundamental stages involved is key. At Topweld General Engineering, we observe these core steps in every project, ensuring quality and efficiency from start to finish.

Let’s explore the essential stages that define a successful custom metal fabrication project:

1. Design Review & Planning

2. Prevision Fabrication

3. Assembly & Finishing

4. Quality Assurance & Dispatch

1. Design Review & Planning

Often underestimated, the meticulous review of project drawings is paramount for successful fabrication. These drawings, the “blueprint” from design engineers, guide every aspect of the build. The purpose of this stage is to detail precisely how each component will be made, assembled, and ultimately form the completed product.

Advanced CAD software is commonly leveraged for unparalleled accuracy and complexity in design. This powerful tool provides detailed graphical descriptions, precise measurements, and helps document design iterations. All documentation – from individual component parts to sub-assemblies and final product assembly drawings – must be thoroughly reviewed and approved before moving to the fabrication stage.

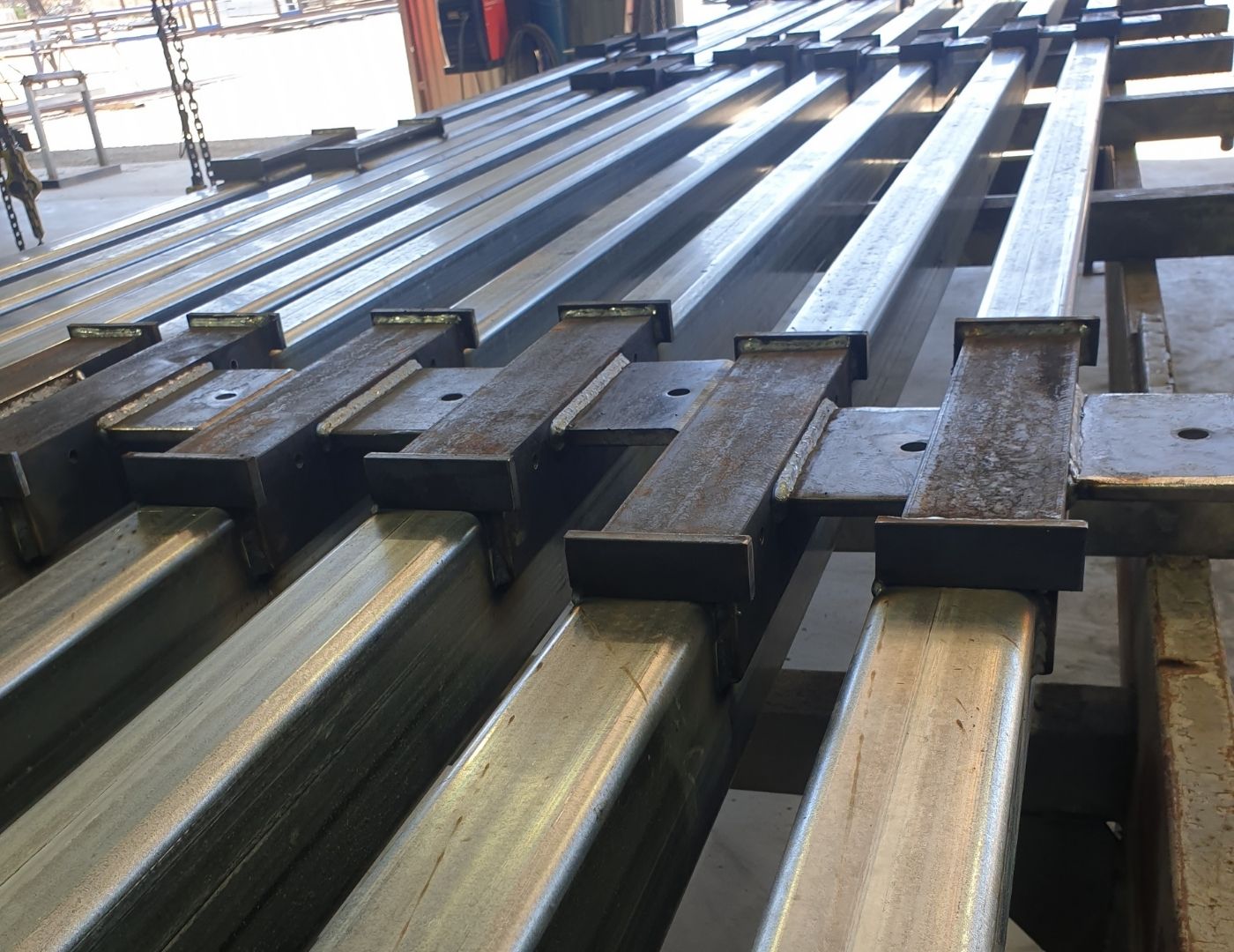

2. Precision Fabrication

This stage brings designs to life through a diverse range of processes. A well-equipped fabrication facility houses state-of-the-art machinery and tools for:

Cutting: Utilizing various cutting techniques.Punching & Shearing: For precise material preparation.

Forming & Bending: Shaping raw metal to exact specifications.

Welding: Employing various methods to join components securely.

Custom fabrication projects work with a wide range of metals and their alloys, such as stainless steel, carbon steel, aluminium, copper, and brass. Processes are adapted to suit the material and desired end product, ensuring exceptional results whether for a unique piece or a production run.

3. Assembly & Finishing

Once individual metal components are expertly fabricated, they move to assembly and finishing. Here, parts are precisely fitted together using a variety of techniques. Assembly can involve:

Diverse Welding Methods: Ensuring strong and reliable joins.

Fastening Operations: Including PEM-setting, weld nut fastening, stud welding, or automated pneumatic riveting.

After assembly, products receive final touches before dispatch. This may include applying protective layers like rust-resistant paint or powder coating, specific color finishes, glazes, or surface treatments such as brushing, polishing, and shining. Decals or insulators may also be applied.

4. Quality Assurance & Dispatch

Beyond core manufacturing, ensuring completed products are properly packaged and shipped is crucial. Comprehensive Quality Assurance (QA) is vital to ensure every item meets the highest standards before it leaves a facility.

For packaging and shipping, especially for larger or export items, products often require custom crating, skids, pallets, and other wood packaging materials. Critically, all wood packaging used must adhere strictly to Australian biosecurity import conditions, which are compliant with international protocols like IPPC (International Plant Protection Convention) and are ISPM-15 certified (International Standards for Phytosanitary Measures, No. 15 regulations). This ensures secure transit and timely delivery, guaranteeing satisfaction upon arrival.

Ready to start your custom metal fabrication project?

To discuss your specific needs or learn more about our comprehensive services, contact Topweld General Engineering Pty Ltd today. Our team is ready to collaborate and bring your vision to life.