Introduction

When it comes to custom fabrication, the strength and safety of the finished product depend not just on skilled workmanship but also on systematic oversight. A quality control (QC) system ensures that every stage of the fabrication process — from material selection to final inspection — meets strict performance, compliance, and safety requirements. Without QC in place, projects risk delays, rework, and costly failures.

In this article, we outline the key reasons why businesses should hire metal fabricators with a quality control system, and what benefits this delivers to projects across various industries.

1. Ensuring Compliance and Safety

One of the most critical functions of a quality control system is ensuring compliance with industry regulations and Australian safety standards. Fabricators who follow structured QC practices document every step of the process, maintain traceability of materials, and ensure welds and assemblies meet specifications.

By working with a fabricator that prioritises compliance, you minimise risks of unsafe equipment, regulatory breaches, and future liability. This is especially important for industries such as food processing, energy, pharmaceuticals, and construction where safety is non-negotiable.

2. Consistency and Reliability

Without QC, every batch of fabricated components might differ slightly in quality or performance. A strong quality control system introduces repeatability, ensuring that all parts and assemblies meet the same benchmark.

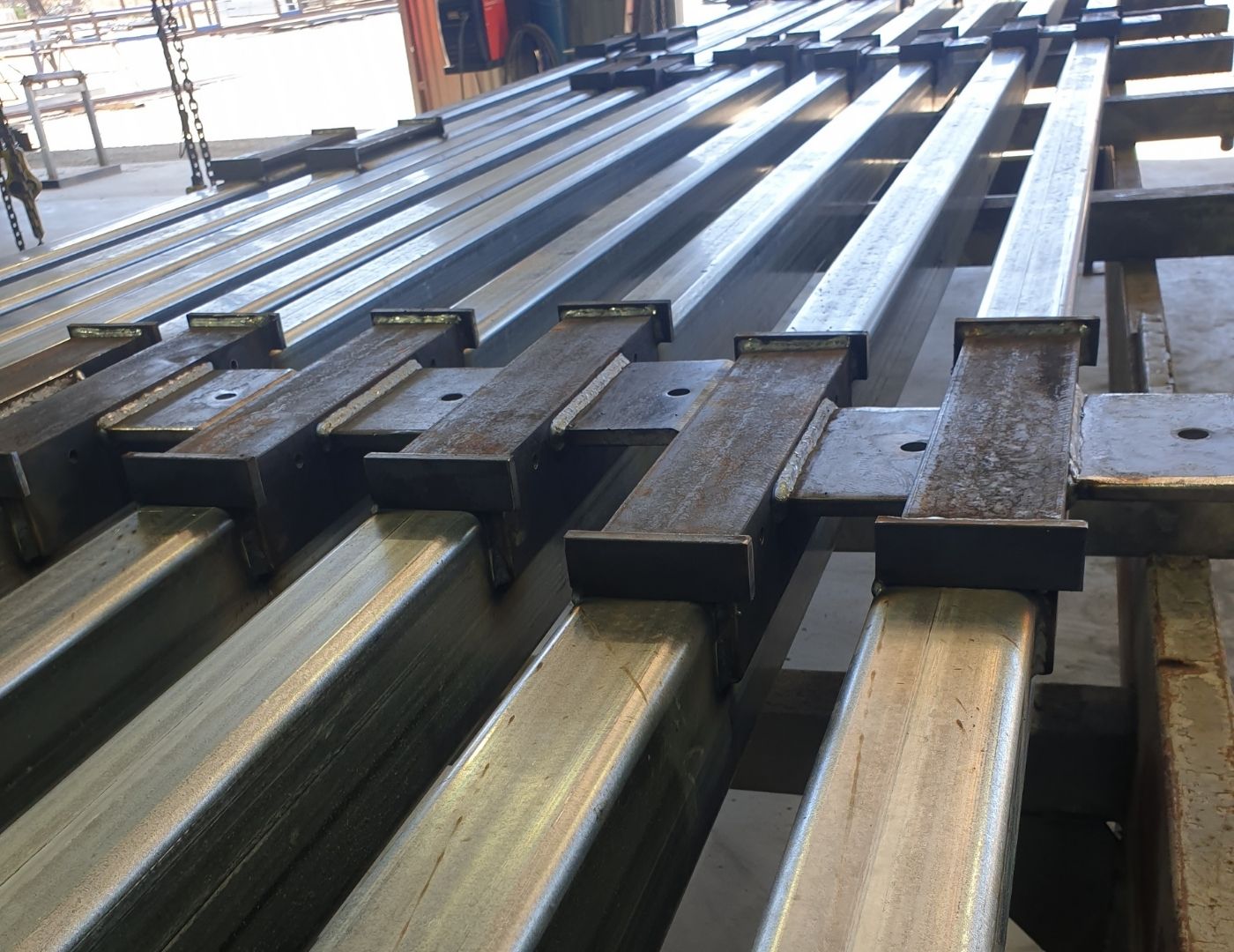

This consistency is essential in projects that require multiple identical components, such as stainless steel tanks, structural frameworks, or production line installations. When quality is consistent, clients gain confidence that their project will function as designed — reducing the need for costly adjustments later.

3. Early Detection of Errors

Fabrication involves multiple technical processes — cutting, forming, machining, welding, and finishing. If errors go unnoticed at one stage, they can compound into major problems during final assembly. A quality control system includes inspections and checks at every stage of production, ensuring defects are caught early.

This proactive approach prevents rework, reduces waste, and saves both time and money. It also ensures that finished products leave the workshop ready for installation and long-term service.

4. Cost Savings Over the Project Lifecycle

While some clients assume that fabricators with a QC system may be more expensive upfront, the opposite is often true. Projects completed under strict quality control experience fewer failures, less downtime, and reduced maintenance costs.

For example, properly inspected welds are less likely to crack or corrode, and components manufactured to exact tolerances require less re-adjustment during installation. Over the lifespan of a project, these savings add up — delivering better overall return on investment (ROI).

5. Improved Communication and Documentation

Another advantage of hiring fabricators with QC systems is the emphasis on documentation. Quality control involves maintaining detailed records of materials used, inspections performed, and test results. This documentation not only supports compliance audits but also improves communication with clients.

Clients receive full transparency on how their project was executed, which builds trust and provides assurance that the finished product meets agreed standards.

6. Reputation and Professionalism

A fabricator that implements a quality control system signals professionalism, attention to detail, and commitment to excellence. For clients, partnering with such a company reduces risks and enhances project outcomes. For fabricators, QC strengthens their reputation in the industry and ensures long-term client satisfaction.

When you hire a fabricator with robust QC practices, you’re not only investing in a product — you’re investing in the reliability and integrity of the partner delivering it.

Conclusion

The decision to hire metal fabricators with a quality control system is one of the smartest investments a business can make. From compliance and safety to consistency, cost savings, and professionalism, QC underpins every aspect of project success.

At Topweld General Engineering, quality control is embedded in our processes. Every project — whether a stainless steel tank, structural framework, or industrial installation — undergoes strict checks to ensure it meets the highest standards. By choosing a fabricator with a QC system, you protect your investment and secure peace of mind that your project will perform reliably for years to come.